What is Granite?

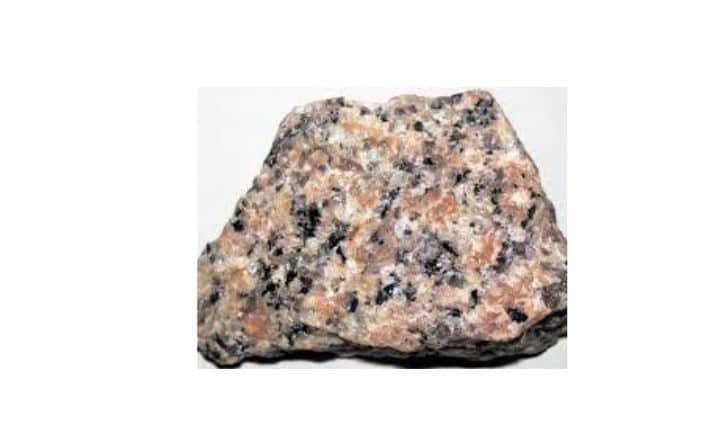

Granite, an intrusive igneous rock, stands as one of Earth’s most iconic and abundant rock formations. Formed deep beneath the Earth’s surface through the slow crystallization of magma, granite typically consists of quartz, feldspar, and mica, creating its distinctive speckled appearance. The cooling process, occurring over millions of years, allows large crystals to form, resulting in the characteristic coarse-grained texture that makes granite instantly recognizable.

The formation of granite mining represents a fascinating chapter in geological history, with deposits found across every continent. Its composition varies slightly by region, leading to a spectacular array of colors and patterns, from classic gray and pink to blue, green, and black varieties. This natural variation, combined with its durability, has made granite a prized material throughout human civilization.

Uses of Granite

Construction and Architecture

In modern construction, granite serves as a premier building material, particularly in high-end applications. The material’s versatility shines in residential construction, where it transforms kitchens and bathrooms through elegant countertops and vanities that combine beauty with practicality. In commercial architecture, granite facades grace many prestigious buildings, providing both aesthetic appeal and lasting durability. Interior designers frequently incorporate granite into their projects, utilizing its natural patterns and colors to create striking visual statements in floors, walls, and decorative elements.

The outdoor application of granite demonstrates its exceptional versatility and durability. Landscape architects incorporate granite into their designs through pathways, garden features, and outdoor living spaces. The material’s natural resistance to weathering and its ability to maintain its appearance over decades make it particularly valuable for exterior applications, from simple garden pavers to elaborate water features.

Industrial Applications

Beyond its decorative uses, granite plays a crucial role in various industrial applications. The manufacturing sector relies on granite’s dimensional stability and smooth finish for precision surface plates used in quality control and measurement operations. In civil engineering, granite’s durability makes it invaluable for infrastructure projects, where it serves as a fundamental component in road construction and railway systems.

Properties of Granite

Physical Characteristics

The exceptional physical properties of granite stem from its igneous origins and crystalline structure. Its high compressive strength enables it to bear enormous loads without deformation, making it ideal for structural applications. The interlocking crystal structure creates a natural resistance to water absorption, contributing to its remarkable durability in various environmental conditions. This same structure provides excellent heat resistance, allowing granite to maintain its integrity even under extreme temperature variations.

The material’s resistance to weathering and chemical degradation ensures its longevity in both interior and exterior applications. Natural frost resistance, coupled with minimal maintenance requirements, makes granite particularly valuable in regions experiencing severe weather conditions. These properties combine to create a material that not only performs exceptionally well but also maintains its appearance and structural integrity over generations.

Aesthetic Properties

The visual appeal of granite lies in its unique formation process, which creates distinctive patterns and color variations that cannot be replicated artificially. The slow crystallization of different minerals produces a depth and complexity in the stone’s appearance that makes each piece unique. When polished, granite develops a lustrous shine that enhances its natural beauty while maintaining its practical durability.

Granite Mining

Extraction Methods

Modern granite quarrying represents a sophisticated blend of traditional knowledge and cutting-edge technology. Quarry operators carefully analyze the stone formation to determine the optimal extraction method, considering factors such as the stone’s natural grain and potential stress points. Advanced cutting techniques, including diamond wire saws and controlled splitting methods, allow for precise extraction while minimizing waste and maintaining the stone’s structural integrity.

Processing Techniques

The journey from raw stone to finished product involves multiple stages of careful processing. Initial cutting establishes manageable block sizes, followed by more precise dimensional cutting to meet specific project requirements. Surface finishing techniques enhance both the aesthetic and functional properties of the stone, with options ranging from high polish to textured finishes that serve different architectural and design needs.

Environmental Impact of Granite Mining

Environmental Considerations

The extraction of granite presents significant environmental challenges that require careful management. Modern quarrying operations must address concerns regarding landscape modification, resource conservation, and ecosystem protection. Water management plays a crucial role, as both extraction and processing require substantial amounts of water that must be carefully managed to minimize environmental impact.

Mitigation Strategies

Contemporary granite quarrying operations implement comprehensive environmental management systems that address both immediate and long-term environmental concerns. Advanced water recycling systems significantly reduce water consumption, while modern dust suppression methods protect air quality around quarrying sites. Progressive land rehabilitation programs ensure that quarried areas can be restored to productive use or natural habitats once extraction is complete.

Conclusion

Granite continues to exemplify the perfect union of natural beauty and practical durability in construction and design. As technology advances and environmental awareness grows, the granite industry evolves to meet modern challenges while maintaining the timeless appeal of this remarkable stone. The future of granite mining and processing lies in balancing increasing demand with sustainable practices, ensuring that this valuable resource remains available for generations to come.

The enduring popularity of granite in both traditional and contemporary applications testifies to its unique combination of properties. Through responsible extraction and processing methods, granite will continue to play a vital role in human construction and design, maintaining its position as one of nature’s most versatile and valuable materials.