Talc / Soapstone: A Timeless Mineral

Talc and soapstone have been integral to human civilization for thousands of years, serving various purposes from ancient sculptures to modern industrial applications. This versatile mineral continues to play a crucial role in numerous industries while raising important environmental considerations.

What is Talc / Soapstone?

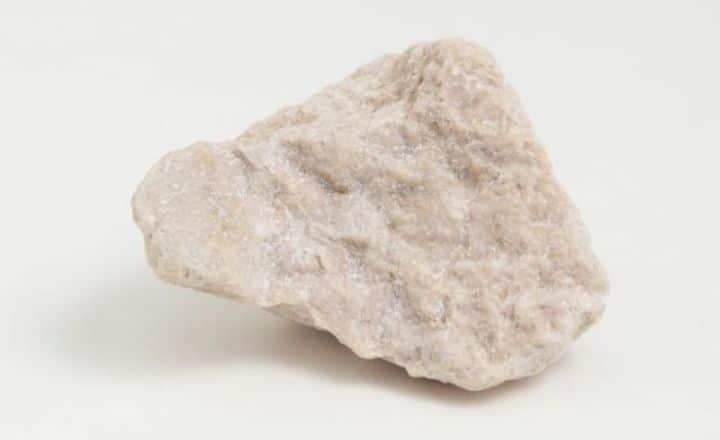

Talc, also known as soapstone in its massive form, is a naturally occurring mineral composed primarily of hydrated magnesium silicate with the chemical formula Mg₃Si₄O₁₀(OH)₂. It is one of the softest minerals on Earth, ranking 1 on the Mohs hardness scale. Soapstone is essentially a metamorphic rock composed predominantly of talc, with varying amounts of other minerals such as chlorite, magnetite, and micas.

The formation of talc occurs through the metamorphism of magnesium-rich rocks or the hydrothermal alteration of dolostone or serpentine. This process typically takes place over millions of years under specific geological conditions, including high pressure and the presence of mineral-rich fluids.

The mineral gets its common name “soapstone” from its smooth, soap-like feel, which is due to its unique crystalline structure. The material appears in various colors, ranging from pure white to grey, green, or brown, depending on the presence of other minerals and impurities.

Uses of Talc / Soapstone

The applications of talc and soapstone are remarkably diverse, spanning both historical and contemporary uses. In industrial applications, talc serves as an essential component in paper manufacturing, where it’s used as a coating and filler to improve paper quality and printability. The plastic industry relies on talc as an additive to enhance products’ structural integrity and heat resistance. Paint manufacturers incorporate talc as an extender and filler, while ceramic producers value its role in creating durable, heat-resistant products.

In the consumer products sector, talc has traditionally been a key ingredient in cosmetics and personal care products, prized for its ability to absorb moisture and provide a smooth feel. Though its use in baby powder has declined due to health concerns, talc remains prevalent in pharmaceutical tablets as an anti-caking agent and in food packaging materials.

Traditional and architectural applications showcase soapstone’s versatility. Its natural beauty and durability make it ideal for countertops and laboratory surfaces, while its heat retention properties have made it a popular choice for fireplace surrounds and traditional stoves. Artisans and sculptors have long appreciated soapstone’s workability for creating intricate carvings and sculptures.

Properties of Talc / Soapstone

The unique properties of talc and soapstone make them invaluable across various applications. Their extreme softness, ranking at 1 on the Mohs hardness scale, combines with natural lubricating qualities to create a material that’s easy to work with yet durable in many applications. The high thermal conductivity and excellent heat retention properties make soapstone particularly valuable in heating applications and architectural elements.

From a chemical perspective, talc and soapstone demonstrate remarkable stability. Their resistance to acids and alkalis, coupled with their hydrophobic nature, makes them ideal for laboratory surfaces and chemical storage containers. The chemical inertness ensures they won’t react with most substances they come into contact with, while their high melting point allows them to maintain integrity under extreme temperatures.

The mechanical properties of these materials further enhance their utility. The natural non-stick surface and resistance to cracking make soapstone ideal for cooking vessels and food preparation surfaces. Despite its softness, soapstone exhibits good compression strength and low thermal expansion, contributing to its longevity in architectural applications.

Talc / Soapstone Mining

The mining of talc and soapstone involves sophisticated processes that vary depending on the deposit’s location and characteristics. China leads global production, followed by significant operations in India, Brazil, the United States, and France. The mining process begins with thorough exploration and assessment, including geological surveys and core sampling to evaluate resource quality and quantity.

Extraction methods vary between surface and underground mining, depending on the deposit’s depth and accessibility. Surface deposits typically involve open-pit mining, while deeper deposits require underground mining techniques. The extracted material undergoes extensive processing, including crushing, grinding, and various separation methods to achieve the desired purity and consistency.

Quality control plays a crucial role throughout the mining and processing stages, ensuring the final product meets specific industry standards. Modern mining operations increasingly incorporate advanced technology and automated systems to improve efficiency and maintain consistent product quality.

Environmental Impact of Talc / Soapstone Mining

The environmental implications of talc and soapstone mining present both challenges and opportunities for sustainable practices. While these operations generally require less chemical processing than many other mining activities, they still impact the surrounding environment. The primary environmental considerations include habitat disruption, dust emissions, water usage, and changes to local topography.

However, the industry has made significant strides in implementing environmentally conscious practices. Modern mining operations often incorporate dust control systems and water recycling programs to minimize their environmental footprint. Land reclamation projects have become standard practice, with mining companies committed to restoring disturbed areas to their natural state or repurposing them for beneficial use.

The relatively low chemical processing requirements and minimal waste production, compared to other mining operations, make talc and soapstone mining somewhat less environmentally intensive. The durability and longevity of soapstone products also contribute to sustainability by reducing the need for frequent replacement.

Conclusion

Talc and soapstone continue to demonstrate their value in modern industry and daily life, offering unique properties that make them irreplaceable in many applications. While their mining and processing present environmental challenges, the implementation of sustainable practices and careful management can help minimize negative impacts.

The future of talc and soapstone usage lies in balancing their industrial importance with environmental responsibility. As technology advances, new applications continue to emerge, while traditional uses remain relevant. The industry’s focus on sustainable practices and responsible mining will be crucial in ensuring these valuable minerals continue to serve human needs while preserving environmental integrity. The ongoing research into alternative materials and more efficient processing methods may help reduce the environmental impact of talc and soapstone mining. However, their unique properties and widespread applications suggest they will remain important industrial minerals for the foreseeable future. The key lies in developing and implementing more sustainable practices throughout the entire supply chain, from extraction to end-use.