What is Calcium Carbonate?

Calcium carbonate (CaCO₃), one of Earth’s most abundant minerals, forms the foundation of countless natural structures, from marine shells to magnificent limestone formations. This versatile compound occurs naturally in several forms, with calcite and aragonite being the most common crystalline variations. Throughout geological history, calcium carbonate has played a crucial role in forming sedimentary rocks, particularly limestone and marble, through various geological processes.

The formation of natural calcium carbonate spans millions of years, often originating from the accumulated remains of marine organisms. These biological deposits, combined with chemical precipitation processes, have created vast limestone deposits worldwide. Modern industrial production includes both mined natural calcium carbonate (GCC – Ground Calcium Carbonate) and synthetically produced variants (PCC – Precipitated Calcium Carbonate), each serving specific industrial applications.

Uses of Calcium Carbonate

Industrial Applications

Industrial calcium carbonate serves as a fundamental raw material across numerous manufacturing sectors. The paper industry relies heavily on calcium carbonate as a coating and filler material, enhancing paper brightness, opacity, and printability. In plastics manufacturing, fine-ground calcium carbonate functions as an essential additive, improving product durability and reducing production costs while enhancing finished product quality.

The construction industry represents another major consumer of calcium carbonate products. From cement production to architectural stone, calcium carbonate materials provide both structural integrity and aesthetic value. Modern construction techniques incorporate specially processed calcium carbonate in various applications, including mortars, concrete additives, and decorative finishes.

Consumer Products and Food Industry

The food and pharmaceutical industries utilize pharmaceutical-grade calcium carbonate extensively. As a dietary supplement, it provides essential calcium for human nutrition, while its use as a food additive extends to antacid medications, toothpaste formulations, and various processed foods. The compound’s natural origin and safety profile make it particularly valuable in these sensitive applications.

Agricultural applications benefit from calcium carbonate’s soil-enriching properties. Farmers worldwide use agricultural lime to adjust soil pH levels, improve crop yields, and enhance soil structure. This agricultural application demonstrates calcium carbonate’s vital role in supporting global food production and sustainable farming practices.

Properties of Calcium Carbonate

Physical Characteristics

Natural calcium carbonate exhibits remarkable physical properties that contribute to its industrial versatility. Its white color, high brightness, and controlled particle size distribution make it ideal for applications requiring precise specifications. The material’s ability to be finely ground while maintaining stability enables its use across diverse applications, from industrial processes to consumer products.

Chemical Properties

The chemical composition of calcium carbonate provides unique advantages in various applications. Its alkaline nature makes it effective in neutralizing acids, while its chemical stability ensures long-term performance in finished products. The compound’s reaction with acids produces carbon dioxide, a property utilized in specific industrial processes and commercial applications.

Calcium Carbonate Mining

Global Production

Calcium carbonate mining operations span the globe, with significant deposits found across multiple continents. Major producing regions include Europe, North America, and Asia, each contributing to the global supply chain. Modern mining operations combine traditional extraction methods with advanced processing technologies to meet increasing market demands while maintaining product quality.

Mining and Processing Methods

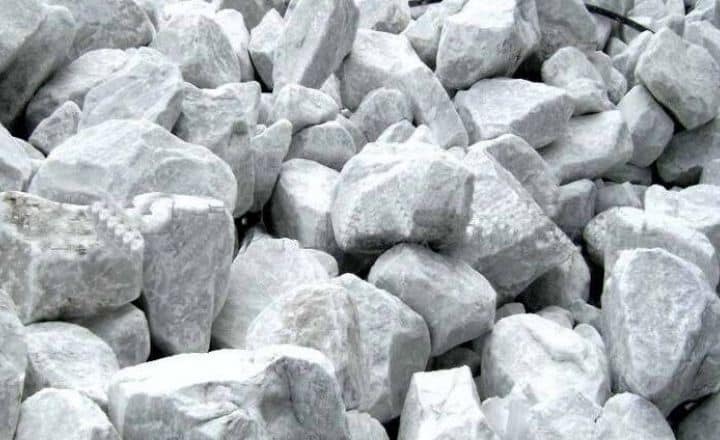

Contemporary calcium carbonate production involves sophisticated mining and processing techniques. Open-pit mining remains the primary extraction method for limestone deposits, followed by careful processing to achieve specific product grades. Advanced processing facilities employ multiple stages of crushing, screening, and classification to produce precisely sized materials for various applications.

Quality control measures throughout the production process ensure consistent product characteristics. Modern processing plants utilize advanced analytical techniques to monitor product specifications, ensuring that finished materials meet stringent industry requirements. This attention to quality control has become increasingly important as applications demand more precise material specifications.

Environmental Impact of Calcium Carbonate Mining

Sustainable Practices

The calcium carbonate mining industry has embraced sustainable practices in response to environmental concerns. Modern operations implement comprehensive environmental management systems that address dust control, water management, and energy efficiency. These initiatives reflect the industry’s commitment to minimizing environmental impact while maintaining productive operations.

Environmental Management

Environmental protection measures form an integral part of modern mining operations. Companies actively manage water resources through recycling programs and advanced filtration systems. Dust suppression technologies help maintain air quality around mining sites, while careful planning ensures minimal disruption to local ecosystems.

Land reclamation programs demonstrate the industry’s long-term commitment to environmental stewardship. Mining companies implement progressive rehabilitation strategies, restoring mined areas to productive use through careful soil management and revegetation efforts. These programs help preserve biodiversity and maintain ecological balance in mining regions.

Conclusion

Calcium carbonate continues to demonstrate its fundamental importance across numerous industries and applications. From construction materials to pharmaceutical products, this versatile mineral remains essential to modern industrial society. Ongoing research and development efforts continue to uncover new applications while improving existing processes.

The future of calcium carbonate mining and processing looks promising, driven by technological advancement and growing market demands. Sustainable production practices and environmental consciousness increasingly shape industry operations, ensuring responsible resource development for future generations. The balance between meeting industrial needs and environmental protection remains a key focus for the industry.

As global development continues, calcium carbonate’s role in various applications will likely expand further. The industry’s commitment to innovation, quality control, and environmental responsibility positions this timeless mineral for continued importance in global commerce and industry. Through careful management and sustainable practices, calcium carbonate mining and processing will continue to provide essential materials for diverse applications while preserving environmental integrity.

This enduring mineral, formed through ancient geological processes, remains vital to modern civilization while adapting to contemporary environmental and technological challenges. Its continued importance underscores the need for responsible resource management and sustainable development practices in the mining industry.